Ultimate Factory - Batch Flow - 5-S - Lean Flow - Earned Value

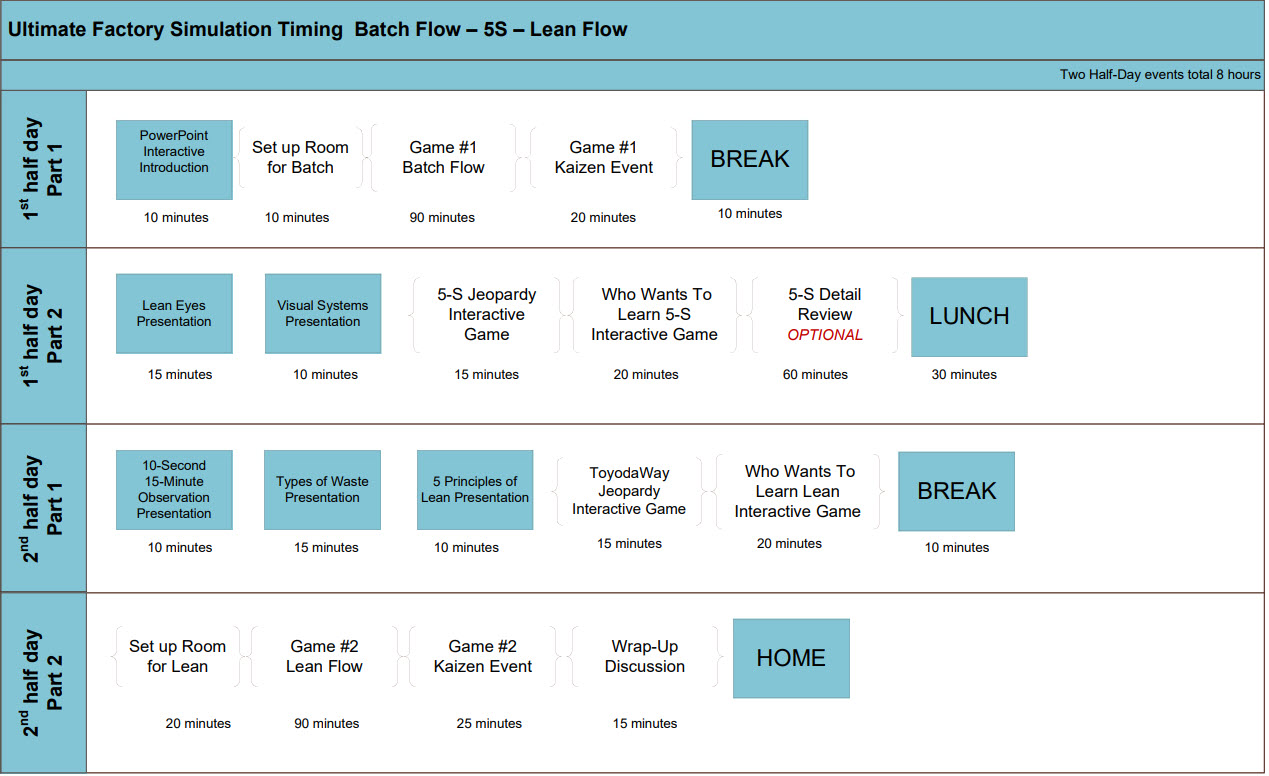

This full day event focuses on understanding a factory, hidden factory costs, eliminating waste, how people learn and how teams work together, and the importance of flow velocity. A batch flow is used to introduce the learning curve and frustrations of a batch push. Participants are then introduced to Kaizen, or voice of the people. Then the team is introduced to the 5-S philosophy, tools and strategies as developed by the Toyota Motor Company. Following 5-S is a presentation on the 5 principles of Lean Flow.

After the 5-S familiarization presentation, the students are invited to participate in a series of fun games which repeat and focus the concepts and terms of 5-S. See 5-S Game Set on the Team Development product page for details.

The students are invited to participate in a series of fun games which repeat and focus the concepts and terms of Lean. See ToyodaWay Game Set on the Team Development product page for details.

Next the participants set up a simulated Lean Flow factory, with the 5-S implementation and point of use (POU) inventory, to run the two products again and analyze the earned value difference between the Batch and the Lean flows.

The Ultimate Training presentation is interactive, and the Guide links each of the presentations in seamlessly as the day progresses.

LeanMan Ultimate Simulation Package with 5-S & OPT

The Ultimate Simulation explores Batch Flow, 5-S, and Lean Flow. Now also includes the OPT simulation. The Goal is to use continuous improvement to transform from Batch Flow to Lean Flow using 5-S tools.

LeanMan Ultimate Plus OPT Package