3-Step Heijunka Simulation

This presentation event is part of the Deluxe-Plus Heijunka Lean Factory Simulation Package, or the Heijunka Upgrade Kit can be obtained as an optional purchase for use with the standard Deluxe Car Factory Kit and the other Deluxe-Plus Car Factory Kits. It is included in the Grand Package.

The "Leveling the Waves" presentation presents an alternate way of approaching the function of master scheduling and planning for a lean manufacturing environment. Creating a smooth level work flow out of the chaotic and random customer demand is a challenge in a lean shop, and requires a managed disconnect from the MRP push.

The Heijunka simulation exercise develops a unique approach to visualization of work flow, allowing the planning function to gain control over capacity issues and assure on-time delivery in a mixed-mode production work cell. The simulation exercise is designed to train the planning and scheduling members of the team, but is also an excellent tool to teach work cell operators lean flow methods.

The basic play is centered on the heijunka box, placed in the middle of the table arrangement. The customer, planner and finished goods are on one side, the production assembly and inspection team on the other side. The Customer places orders for the toy cars using Job Order cards on which the model (one of 6) and quantity are checked. The orders are sent to the planner who then uses the "plan rules" developed by the team to load Heijunka kanban cards into the Heijunka schedule box. The operations team pulls the Heijunka cards in sequence and delivers the completed cars to finished goods, where the Customer order is completed and metrics recorded.

NUMBER OF PARTICIPANTS

The team set up is variable but works best with 10 people. Table arrangement and role placement in relation to the Heijunka box is shown pictorially in the facilitators guide book. The facilitator tools include a printed and bound color 49-page guide book and PowerPoint presentation which provides a complete discussion of the Heijunka control methods and includes animated visual simulations of the Heijunka flow in the PowerPoint slideshow.

EVENT TIME

A single facilitator can easily control the team when using the printed and laminated participant instruction placemats provided as part of the kit. The Facilitator guide lists things to observe and point out to the people, comments to add for clarity, and suggestions for improvement.

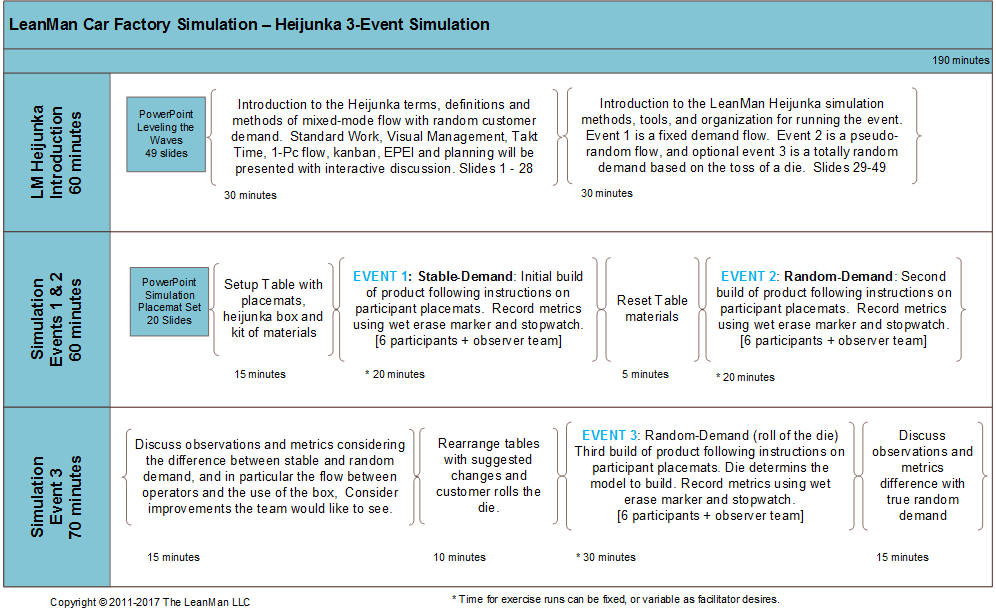

Event time is approximately 1 hour for the slideshow presentation and 1 hr 10 minutes for the simulation, but allow plenty of additional time to experiment with alternate flows. Room size should be a training room or large conference room with at least three tables and room for 12 people.

Deluxe PLUS HEIJUNKA Car Factory Simulation

LeanMan Grand Car Factory Simulation