14-Step Optimized Production Technology - OPT

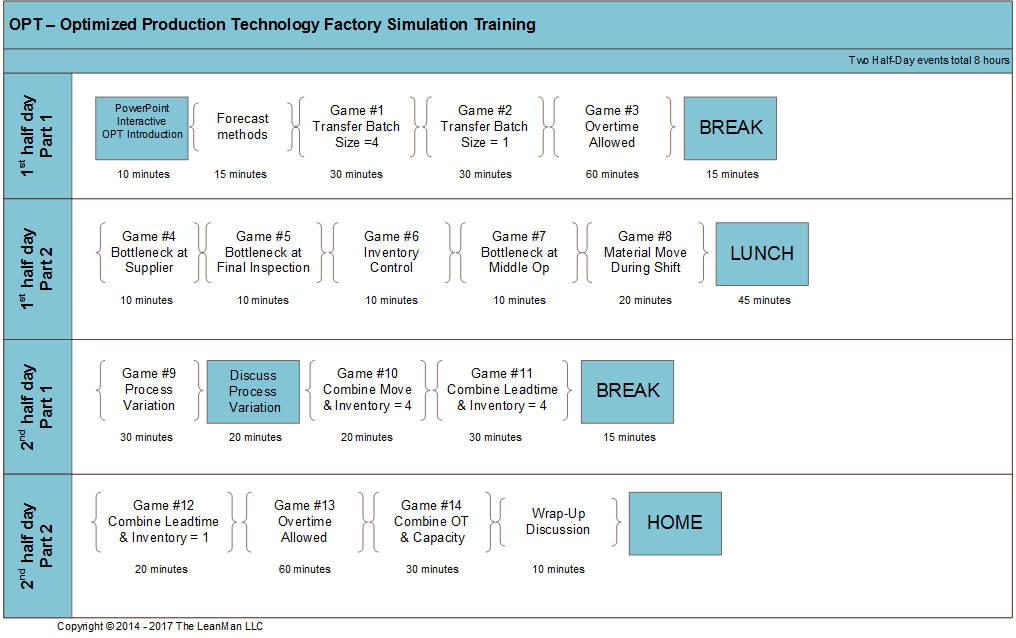

This 14-Step simulation is designed to teach the basic flow of material in a production environment. It uses poker chips as the product and two types of die to simulate capacity.

This fourteen-step simulation begins by performing a Batch push-flow simulation while participants attempt to deliver a transfer batch of four to the customer.

The focus is on hidden waste of supply chain delivery methods, material handling, capacity constraints and so on.

The remaining steps of the simulation test out variations in transfer batch size, the use of overtime, inventory control, issues concerning bottleneck operations, and such. Students make the determination IF and WHEN and WHERE overtime might be appropriate and review the results.

This simulation is intended to teach methods to people who are responsible for product flow and also packs some eye opening information for executives. It becomes the base foundation upon which the Lean Manufacturing Concepts are built. It really speaks volumes about the power of lean.

NUMBER OF PARTICIPANTS

The team set up is 12 people but can be easily changed to accommodate as few as 8 or as many as 16.

METRICS

The QUILS metrics are calculated using either a large flip chart or the Excel file on the CD to calculate QUALITY, UNIT COST, INVENTORY, LEADTIME, and SHIP PERFORMANCE

EVENT TIME

A single facilitator can easily perform the two half day events by using the Participant interactive PowerPoint presentation combined with the facilitator guide handbook. Excel files are provided to Train - the - Trainer in each flow with practice on material flow, the throw of the die, and completing the metrics.

OPT Factory Simulation Game

LeanMan Ultimate Simulation Package with 5-S & OPT

The Ultimate Simulation explores Batch Flow, 5-S, and Lean Flow. Now also includes the OPT simulation. The Goal is to use continuous improvement to transform from Batch Flow to Lean Flow using 5-S tools.