The Lean Factory Simulation begins with the Batch ‘n Queue method based on Adam Smith’s division of labor principles. These were later solidified by Frederic W. Taylor and presented in his 1911 book “The Principles of Scientific Management” (New York: Harper & Brothers). Taylor’s methods became the bedrock for production flows around the world. This batch process is nicely presented in the New Manufacturing Challenge: Techniques for Continuous Improvement by Kiyoshi Suzaki (The Free Press, 1987), and it is Suzaki’s model that becomes the first simulation event. (The Deluxe Kit provides all this history and more in greater detail in the Power Point training presentation.)

The simulations then progress through the techniques of one-piece cellular flow, continuous flow with Kanban signals, ending with a lean flow using a pull system. Along the way, additional lean concepts are layered onto each event, such as Value Stream Mapping, learning to see waste with the NVA test, and more. There are four main flow concepts presented, with four variations of each type described in the kit, plus many suggestions for training the workers to think lean. Please see the Suggested Training Syllabus on the References tab.

Key learning objectives of the simulation

- Understanding Lean concepts of one-piece flow, pull systems, inventory reduction, and more

- How production flow has followed batch ‘n queue over the last 100 years, and why change is needed

- How to see where waste and inefficiency exists in each type of flow

- How line imbalance and inventory stockpiles affect the customer

- How to see the whole value stream

- How to optimize the efficiency of the whole stream versus the efficiency of the individual process

- How to identify Value Adding and Non-Value Adding activities

- How to seek continuous improvement, one step at a time

- How to Think Lean

The Evolution of Lean presentation is included with each Deluxe level training product. It is a historical approach to understanding lean principles and modern theory of operations management. The purpose of this presentation is to lay the foundation for understanding why offices, factories and in fact any group of people in business together operate the way they do, and why the application of the lean concepts is so important in today's time-based competitive global economy.

Success or failure of your lean journey depends upon how well the team buys into the concepts, and the lean leadership that is provided to them. Most groups operate in the traditional "functional separation" mode based on a century old concept that says the best way to manage the big organization is to break it into small functional organizations, and if each small functional group then optimizes for its own best goal that somehow by default the big organization would be optimized. Wrong!

Lean principles training helps us to see the value stream that flows through and between each of the small groups and to help us set goals that will optimize the value for the entire organization. The Evolution of Lean presentation lays the path from traditional batch 'n queue methods of the twentieth century to the lean flow of today.

The concepts presented relate directly to the Lean Factory Simulation Kit training guide and provides the team with the ability to test out the theories before taking them to the shop.

A Bit of History

At the turn of the last century companies were mainly mom and pop shops where products were craftsman items produced out back by pop while mom did the accounting at the kitchen table. As the business grew the functions of accounting, purchasing and production plus any other needs were handled by people brought in specifically to focus on these special duties.

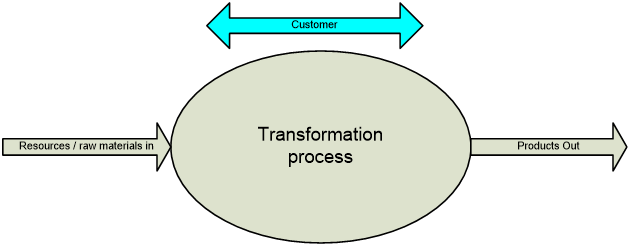

Typically, they shared a large office space and communication between members was very informal. Collectively they formed the transformation process to take raw inputs into the process and deliver a finished product out to the customer.

Management of these large business models, and more specifically improving their efficiency, became the work of Frederic W Taylor.

Taylor saw the business being run as one large transformation problem. Materials and resources were inputs, and products were outputs.

As business grew communication between the functional elements and the owner became strained, efficiencies were lost in the chaos. Taylor began his studies with the manual labor required to perform tasks, and the improvement of labor efficiency by careful study of the component parts of each task element, i.e. movements of the worker.

This eventually led Taylor to publish the discovery of the "one best way" process for each type of work task. His principle led to the development of industrial engineering as a career for process design.

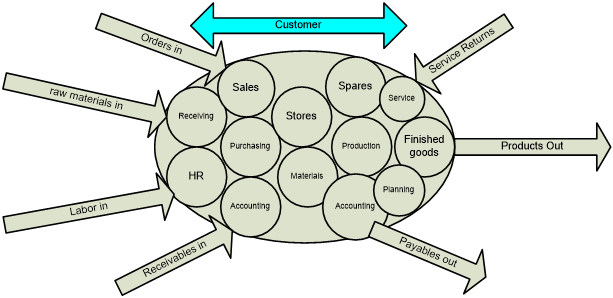

As the business continued to grow the special functions became formalized Functional Departments within the transformation process with separate offices and independent managers. Formal communication between the departments became ridged as well with specific information needs placed on forms to be filled out and all documentation requirements to be filed.

Frederic W Taylor’s 1911 Scientific Principles divided the “big business” transformation process into smaller and more easily managed functional departments tasked to design their own “one best way” processes under the skillful eye of trained industrial engineers and managers, and then turn them into formal standards, with each department isolated and operated under independent management, where department goals are optimized for each function’s own best interest – even to the detriment of overall company efficiency.

The theory was based on the concept that if each function was optimized for their own greatest efficiency then the whole company must by default become optimized.

These Functional Departments were designed to provide the owner with an element of control over the large business where specific focus could be applied where and when needed, but on a smaller scale the owner could manage one element at a time.

The result of this focus on optimization of each functional element department is a dedicated skill set development within each department, an understanding of standards and processes that can only be performed by members of the select team and therefore limited to the availability of only those people, while others wait for the output.

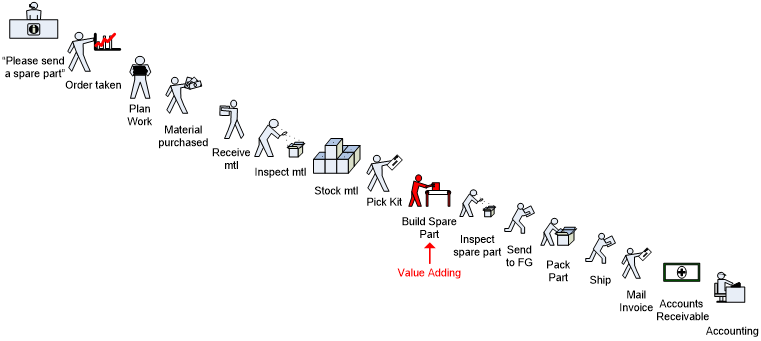

This results in long lead times to produce the overall product of the operation, even when the only value adding step, the one for which the customer is willing to pay, may be buried deep in a stream of non-value adding tasks.

Materials to be passed between the functional departments typically require queues and delays while waiting for the next department to clear the way to receive it, and then perform their function. Most departments have an INPUT queue box to hold requests until they can be processed, and an OUTPUT queue box to hold completed materials or forms waiting for that special person to arrive to pick up and transport the item to the next departments INPUT queue. This is what is referred to as independent process flow.

Paperwork forms must be completed, approvals obtained, priorities analyzed, resources assigned, work tasks queued up and eventually the work completed. Let’s visualize the delivery of a spare part requested by a customer, and the functional elements that the process interacts with from order receipt to payment acknowledged. Imagine the formal documentation required between each step in the sequence, the formal forms and approvals, and the queue delays between each activity.

Interactive contact between departments not under direct supervision of the value producing department manager require queue and delay while each interacting department sorts out priority, resource availability, sometimes additional authority and responsibly and then reaches a mutual agreement on "when and how."

The result of this focus on optimization of each functional element department is a dedicated skill set development within each department, an understanding of standards and processes that can only be performed by members of the select team and therefore limited to the availability of only those people, while others wait for the output.

This results in long lead times to produce the overall product of the operation, even when the only value adding step, the one for which the customer is willing to pay, may be buried deep in a stream of non-value adding tasks.

Value Stream Management is the process of measuring, understanding, and improving the information flow. The value stream is mapped with all of the individual interactions required of all associated functional departments or tasks that are part of the flow necessary to keep Cost, Service and Quality for a company's products and services as competitive as possible. Then the operation steps are realigned to optimize flow from customer order all the way back to the source of materials, and any operation that can be moved to a background function and out of the way of flow is thus moved, and production velocity and throughput are brought to the forefront of the process to optimize on the customer’s needs, not the individual internal departments of the company.